Reinventing Physical Retail

How Might We

Create a new kind of store experience with the world’s most advanced Just Walk Out Shopping Technology?

Work

Computer Vision, UX, Human Centered Design, Branding

Company

Amazon

Year

2014-19

By decoding the complex language used to teach the world's first autonomous store to work with minimal errors, while setting a high bar for the customer experience.

TL;DR

-

Founding design member defining 0-1 AI driven experiences and evolutions.

-

Responsible for the store Digital and Physical character to build customer trust in Amazon Food and AI.

-

Design Lead in Amazon Food initiatives including Good Food Fast, Amazon Meal Kits, and Amazon Kitchen products.

-

Led executive leadership workshops and presentations.

-

Rapid Prototype and beta testing research with users.

-

Help lift technological restrictions that allowed Amazon Go to scale into 28 locations along with the translation of technology into 44 Amazon Fresh stores.

Deeper Project Dive

Background: In 2014, I connected with the innovations team at Amazon about a shiny new thing. I took on the challenge, not knowing that I would be helping re-invent physical retail until Day 1.

I had the fascinating and impactful role of defining every aspect of the brand's expression and experience that would help "teach" the store to work, bridging physical and digital touchpoints while working with hard technological requirements in computer vision, sensor fusion, and AI with a mission to reinvent physical retail.

A typical project spanned around 3-4 months from beginning to end. I worked on over 20 tech-enabled product experiences, always iterating and improving the design while helping evolve the technology that made the store work like magic. I also created tool-kits that formed the foundation for our BETA and initial store launches.

The Team: Aaron N. (Design Director), Ashley A. (Creative Director), Maren C. (Principal UX Designer), Kristy K, (Senior Copy Writer), Ashley B. (Store Design Lead), Ashley S. (Program Manager), Engineers, Machine Learning Scientist, Cross-Function Leaders, Store Ops.

My Role: Lead Innovations designer responsible for creating the vision and delivering human-centered, tech-driven, solutions in brand identity, rapid prototype, systems design, environmental design, and digital + physical product launches.

First Challenge: Perception

Amazon is known for one-click shopping, customer ratings, prime convenience, innovation, fast delivery, and brown craft boxes with everything from A to Z delivered to your door.

How might we gain customer trust with freshly prepared food, without the baggage of convenience stores’ perception of mass-produced food in a warehouse?

Second Challenge: Codes

The goal of removing checkout lines from a customer’s shopping mission came with huge challenges. One of them, codes.

QR Codes

Airport Codes

Bar Codes

Marker Codes

Aruco Codes

Matrix Code

Aztec

Just Walk Out

Computer vision, deep learning algorithms, and sensor fusion were weaved into the fabric of the store. Each feature with its own hard technological requirement. This meant that a customer would experience codes throughout their entire journey from the moment they use the app to enter the store, to when they just walked out. The team laser-focused on prioritizing strong tech dependencies with the goal of completely removing restrictions in the future.

Automation & Errors

The scenario when I joined is illustrated here. The beta store environment had the true expression of an automated test site but it was far from delightful. The various codes were essential to reduce error rates and gaining customer trust. My job was to find, or invent, solutions that minimize the technical jargon around delicious foods and reduce error rates to below 5%. Anything more would not meet business goals.

.jpg)

Solving the Hardest Thing First

Delicious fresh-made irresistible food

The lunch crowd is accustomed to fresh-made foods ready to be enjoyed anywhere.

One unique code per product line

Variable data code with a minimum size of .25" "on or off" squares pixel on all fresh, hand-made foods.

.jpg)

On-the-shelf restrictions

Food needs to be packaged so that it sits flat and stable with the "top" always up.

Understanding Our Customer

Mid 30's

Single

Working Professional

Busy on-the-go eater

I don't have time to think about lunch. I'm in meetings all morning and have about 20 minutes to get something (typically) not very good, quick.

Paul Sandu | Tech Program Manager

Gathering Requirements

Labels with a unique code need to be printed in back-of-house, on-demand. The ingredients could change at any moment and we wanted to give customers accurate information on the hour if needed.

-

Scalable

-

Food safe

-

No designers needed

-

Back-of-house printing

-

No color

-

Can break the square grid

-

Must be tech validated

-

A "pixel" has to be on or off

-

High contrast

Code Design Development

Testing & Outcomes

.jpg)

Check-ins

Worked directly with engineers, data scientists, and developers on code solutions.

Data Scientists: Nataliya S. & Joseph T.

Testing

Code direction passed initial testing with great outcomes. A new label requirement was identified during this test.

050816_Page_1.png)

Rules

Final “tag” design was defined as a block of 4x6 modules of primitive diamonds and circle shapes. The rules were 20% diamond and 80% Circles

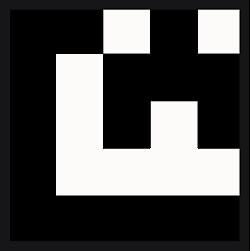

Solution: Dynamic Code

I worked on the brand & Identity in conjunction with the code systems. The requirements lead to a solution that merged brand identity with tech requirements into a brand pattern code. Primitive with just enough design that could be “sprinkled” through the environment as part of the brand experience.

״Very Smart"

Gianna P.

VP Design, Amazon Go

Design Gallery Day Feedback

"I did not think it was possible to reimagine the code but you did it and it's beautiful."

Nataliya S., Data Scientist

"Great work. The labels work as a tamper proof seal and saves labor time and cost by not adding another touchpoint."

Julia G., Packaging Program Manger

"It's modern merchantile. Simple and let's the food be the hero."

Ozgur D, Director

"The orange bag looks great. A new Seattle icon? I want to use it for everything."

Nancy C. Senior Marketing Manager

The large Aruco tag made it possible for us to maintain a 6-8% error rate, while the data matrix code on the label helped us track inventory with 100% accuracy. In an effort to continually innovate for the customer and reduce and correct errors quickly to meet business goals, an airport code became a new requirement. Faster corrections would help build trust by ensuring accurate information on customer receipts. Customers should only have to wait a few seconds after leaving the store, if not immediately, to receive their receipt.

I remember a tense discussion in a meeting, where our Design Director wanted to maintain a high bar for the customer experience and pushed back against adding another element to the label. However, Tech needed this requirement for fast corrections. It was an additional thing for the customer to figure out, but then I remembered a student project I worked on that had a deli item number as part of the visual identity. I suggested using a recipe or menu number that tells a food story. The group of 20+ people in the war room reacted positively to the idea, and we quickly mocked it up and tested it. The number had to be 350 points tall, bold, and clear to function properly, as illustrated in the label specs. We also added it to the bottom of the container for instances where the product ended up upside down.

96.3%

Accuracy

6 sec.

speed of correction

War Room

The team took over a conference room for 3 weeks. We hosted workshops, working sessions, and stakeholder meetings.

Inventor Award

Awarded inventor pattent 10,507,949

Re-inventing the to-go container

To complete the sandwich experience and meet the requirements of stabilizing the code horizontally flat on the shelf, I thought about the correlation between an Amazon packaging box and the familiar to-go container. Both Kraft in color plus friendly and approachable. That's when I came up with the idea of taking that vernacular, which people are already used to seeing as part of freshly prepared take-out, and creating a delightful moment by letting the box pop flat into a plate with the tear of the label. The same label that was required for our tech to work, making it work harder for the customer experience as a tamper-proof evidence seal.

Designing the shelf edge experience

Food is hero

Black shelf edge with black tickets so product and food are first in the hierarchy.

Product information correlation

Black shelf edge with white tickets directly below the product.

Shelf edge forward

White shelf edge with white tickets makes the shelf edge more pronounced.

Vision sensing technology needed a way to calibrate throughout the day. Large code markers made this easy on the tech. My task was to convert these codes into a more pleasing visual so they receded on the shelves but still worked for tech. These codes, along with the data matrix codes on each ticket, would create a lot of visual noise. Promotional tag plans like sale, local, or limited-time offerings would compete with our first tenet of “food is hero.”

Since Amazon did not have a physical presence with an established ticketing system, the Amazon Go team had to create a comprehensive system from scratch. I was the main designer working with cross-functional team members to get alignment on this 5-month project, exploring all possible outcomes to create a system for different zones in the store that scaled. The areas included: Center Store, Wine & Beer, Home Meal Replacements, Meal Kits, and Grab-and-Go Lunch.

The final ticket and marker code system is now in use. The Center Store tickets consist of four different templates with two different paper types. The Home Meal Replacement (HMR) selection was created with its own unique variable data and variable-width system designed to read well at a 7-3ft distance. The Wine & Beer zone was designed to be an immersive experience for both novice and expert wine drinkers.

The markers are spread out above the product tickets as dots that, together, make a solid stripe and are silkscreen printed onto the metal of each shelf. The codes were successful in calibrating throughout the day.

100%

Accuracy vision sensing calibration.

$5k

Minimum monthly savings by minimizing ticket sizes and printing at back-of-house.

Q3-2016

Business goals met.

Ticket updates to meet new U.S. state requirements

Entry key

The Go Design team was small and scrappy, As the primary designer focused on store brand experience design, I was tasked with working with our UX team to rethink the entire entry key experience. I gathered requirements to create a seamless and intuitive user experience.

The design shown here was used for beta testing in previous months, with the latest design being the silhouette shape of an actual key.

-

Make the QR-code more beautiful, playful, and elegant.

-

Size must be 1.9 cm x 1.9 cm or larger.

-

Color has to be uniform; primary colors test well.

-

Keep 2-4 millimeters of clear space around the code.

-

Include a welcome message

.jpg)

Testing

The team faced the challenge of incorporating a mandatory QR code into the entry key experience while adhering to timing and logistics constraints. For security and safety reasons, a unique code would populate every few seconds.

My solution was to incorporate the code into the brand expression by placing it diagonally to create a diamond shape that fit the primitive pattern of circles and diamonds already established. This added a special, dynamic, and possibly ownable touch. We evaluated several ideas, but the diamond design was the one everyone gravitated towards. The team began beta testing the "key" while identifying the right size for the code on the screen.

As part of the exploration, I worked with the UX team to standardize all fonts and icons to ensure brand cohesion. I also designed the app icon for all smartphone devices, standardized product photography in the app, and art directed photoshoots for categories, marketing material, and header images. Additionally, I collaborated with the UX Principle lead on the intro screen to create a seamless and engaging user experience.

App UX/UI Contribution

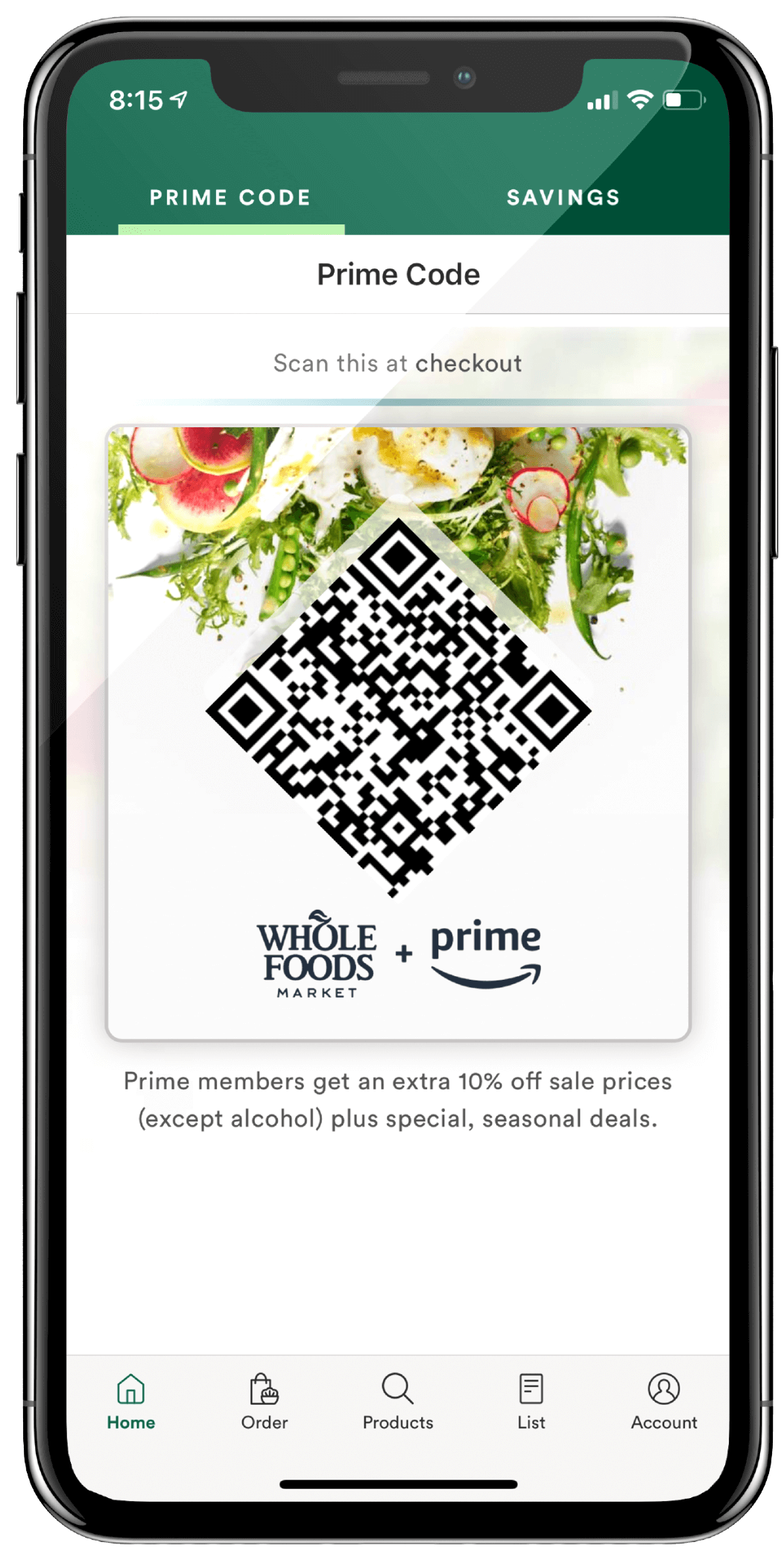

Whole Foods

Whole Foods was acquired by Amazon during my time at Amazon Go, and Prime was adopted into their store experience along with the Diamon QR/Aztec code. This is now an “ownable” shopping experience for Amazon and all its physical shopping stores.

Product Photography

The product selection strategy was underway during the internal beta tests. The rough process I was exposed to went as followed:

Connect with local vendors who have a big following > Pass taste and quality test > Photograph by store associates, upload to corporate database

Store associates had no standards and having products professionally photographed in a studio was not scalable due to localization. For example, we could not ship fresh items from Chicago to the studio in Seattle and have an appetizing controlled photoshoot. So we needed to come up with a solution that could be done by any store associated with point-and-shoot camera knowledge.

The solution was a tabletop kit composed of a camera, tripod, two lights, a soft lightbox, with guidelines and standards.

Overview of pages from the comprehensive Single ASIN guidelines below.

Photography as codes

I was the lead designer for the Amazon Meal Kits product and solved the need for codes on each item by creating a templated layout with instructions on how to create visually unique compositional flows. Vision sensing technology identified each product as unique through photography, color, and name.

Label codes 2.0

The public launch of our first store helped us gain a ton of insight from real customers while allowing the technology to adapt to new scenarios. It was time to push our tech to new limits.

We still needed codes, but the Amazon Meal Kits project gave us new parameters to work with and data to validate a new direction. That insight, along with the push from leadership to add more delicious foods to our menu lineup, gave cross-functional team members a reason to come together on this new initiative.

Perimeters and restrictions:

-

Duration 3-4 months

-

Customer forward

-

Appetizing food forward

-

Maintain technology error rate extremely low

-

Scalable solutions with a light design touch (low production)

-

Unique visual composition per product line

-

High contrast design

-

Branded Amazon Go

_Page_08.jpg)

Words as codes

The typographic solution came to mind by looking at how each letterform was unique in shape. Ingredients are usually composed of at least 3 different letters. If a customer is shopping on the shelf, a large word from a distance would help narrow their selection. A word can become more unique by creating a visual space between letterforms when introducing an outlined letter. This effectively makes two very similar words like “Chicken” unique by alternating the outline in a letter so it differs from the other use case. The customer still reads an appetite-opening KEY word, while tech identifies it as a unique product.

My sketch became so inspirational to the teams that they wanted me to replicate the hand-made vernacular into the identity system since it added a lot of warmth to the presentation. I learned how to create a custom font for easy production.

Working

Towards a

Brighter

Future

A/B Testing

The 3rd floors kitchen area was often used for quick feedback on tight project schedules. I tested two scenarios for customer perception of fresh: color and b/w labels. 100% of the volunteer testers said it was an improvement from the previous ambiguous code. 83 % preferred color text.

✦ PLATFORM

91%

B/W accuracy tech validation

97%

Achieved with additional border line stoke at the edge of label for orientation.

8

8 template sizes spanned across 43 product types keeping the production cost low.

"H U G E upgrade — On behalf of our customers, ‘Hail to you, Fred!'"

Ken Price, Director Product Management at Amazon Go & Amazon Kitchen

“+1 Great partnership! They look amazing all together on the shelf. They take the whole store environment up a notch. Lovely design work, Fred.”

Aaron Nathar, Design Director at Amazon Go

"Amazing job on the new AFP Labels. So impressed by the breath and thought!"

Hafiz Huda, Creative Director at Amazon Go

"Your relentless attention to detail brilliantly translates into Customer Obsession!"